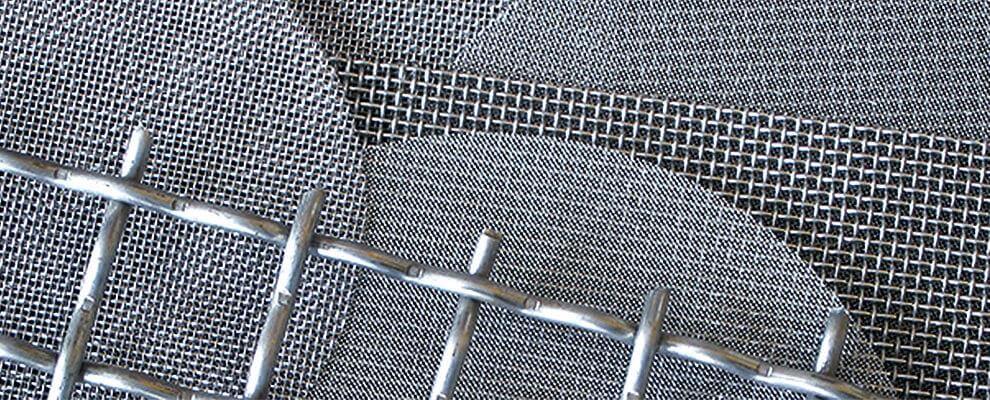

As a material of mesh wire, it is loaded with corrosion resistance assisted with high length and good flexibility. Stainless steel mesh wire is divided into square mesh wire, thick mesh wire (seat mesh), super wide mesh wire that is long 1.2-3.5 meters and 5-8 meters), large mesh wire, and many unique specifications that can be customized according to every user’s needs.

Wire mesh refers to an effortless rendering of a usually 3D object. It does not shade the faces or apply shadows; it merely represents the surfaces as a grid of wire splines. This saves considerable computational resources. In many cases, the software may only have been developed to render 3D objects as only wire meshes to keep the complexity of more realistic rendering.

- Stainless steel woven mesh has high resistance to rusting and corrosion and is widely used across many industries.

- Carbon steel woven and welded wire mesh is affordable, versatile, strong, and magnetic.

- Copper mesh is ductile, malleable, durable, and has high thermal and electrical conductivity.

They are mesh, in which the wires are made from stainless steel and are physically welded at each intersection. The mesh will remain intact and rigid.

It is an ideal option for general use because the welded mesh can be cut down to smaller sizes and shapes like rectangles, squares, or discs without fraying, which can occur when fabricating a woven mesh. Also, high resistance to corrosion, low maintenance, high value for reusability, and usability in extreme conditions, make stainless steel welded wire mesh popular.

Application of mesh wire

It has a wide variety of applications, used in the construction industry, used as industrial sieves, used as chemical filters, architectural decorations, sieves for paper making, for security ( used increasingly in an electrified fence), temporary fencing, and perimeter installation for a limited duration, etc.

Difference between expanded metal mesh wire and stainless steel welded mesh wire

- Expanded metal mesh refers to the steel plate punched and stretched to form a meshed material object; it is divided into the expanded metal mesh and stainless steel expanded metal mesh; it is beautiful and durable.

- It is also known as metal expanded mesh, diamond mesh, iron mesh, metal expansion mesh, heavy expanded metal mesh, pedal mesh, punching plate’ aluminum mesh, stainless steel expanded mesh, granary mesh, antenna mesh, filter mesh, audio mesh, etc.

- Stainless steel welded wire mesh is made of stainless steel wire row welding. The product is processed by automatic mechanical technology; the mesh surface is flat, the structure is firm, and the integrity is vital. Even if it is partially cut or partially under pressure, it will not loosen.

- The difference between expanded metal and stainless steel welded wire mesh is that stainless steel welded wire mesh belongs to metal welded wire mesh, while expanded metal mesh belongs to expanded metal wire mesh.

- The product concept of expanded metal mesh comes from the sheet-like tension mesh product with diamond-shaped mesh that is punched and sheared by a metal sheet by a punching and shearing machine. The expanded metal mesh is made by stamping and stretching, which is sturdy and durable, and the appearance is beautiful and generous.

- Expanded mesh and stainless steel welded wire mesh have similar uses. They can be used in stadium fences, highway guardrails, highway construction protection, etc. Expanded mesh can also be used in mechanical cooling ventilation hoods and mechanical transmission protective covers, filters, and air conditioning equipment, and many more.