As industries evolve, the demand for sustainable architecture in industrial facilities has become more pressing than ever. The shift toward eco-friendly designs is not just about regulatory compliance; it also offers long-term benefits such as energy efficiency, cost savings, and reduced environmental impact. Industrial architects now play a crucial role in incorporating sustainability into large-scale projects like factories, warehouses, and food processing plants.

By integrating renewable energy, waste management systems, and energy-efficient building materials, architects can help industries reduce their carbon footprint while maintaining productivity. This article explores key sustainable solutions in industrial architecture and why they are vital for the future of manufacturing and production facilities.

1. The Need for Sustainable Industrial Architecture

Traditional industrial buildings consume high levels of energy, water, and raw materials, contributing significantly to pollution and resource depletion. In contrast, sustainable industrial design focuses on:

- Reducing energy consumption through optimized building orientation and smart technology.

- Minimizing waste by using recyclable and eco-friendly materials.

- Enhancing efficiency with automation and smart design layouts.

- Lowering operational costs through renewable energy sources and insulation.

Sustainability in industrial architecture is no longer an option but a necessity to align with global environmental goals and corporate sustainability initiatives.

2. Energy-Efficient Building Design

One of the most effective ways to promote sustainability in industrial facilities is energy-efficient design. Proper planning can drastically reduce a facility’s reliance on fossil fuels and lower overall energy costs.

Key Strategies for Energy-Efficient Industrial Buildings:

- Passive Solar Design: Utilizing natural sunlight to reduce artificial lighting needs.

- High-Performance Insulation: Prevents heat loss in cold environments and reduces cooling requirements in hot climates.

- Smart Ventilation Systems: Optimizes air circulation and reduces HVAC energy consumption.

- LED and Motion-Sensor Lighting: Lowers electricity use in warehouses and factories.

These energy-efficient strategies create eco-friendly industrial facilities that are both cost-effective and environmentally responsible.

3. Renewable Energy Integration

Industries are shifting toward renewable energy sources to power their operations. Solar panels, wind turbines, and geothermal heating systems are now key features in modern industrial architecture.

Benefits of Using Renewable Energy in Industrial Facilities:

- Lower Energy Bills: Reducing dependency on fossil fuels decreases operational costs.

- Reduced Carbon Footprint: Cleaner energy sources minimize environmental impact.

- Energy Independence: Industrial sites with self-sustaining energy systems are less affected by power grid fluctuations.

Examples of Renewable Energy Use in Industrial Spaces:

- Solar-Powered Manufacturing Plants: Factories using rooftop solar panels to offset electricity costs.

- Wind-Powered Industrial Zones: Facilities utilizing wind turbines to generate clean energy.

- Geothermal Heating and Cooling: Sustainable temperature regulation for warehouses and storage units.

By embracing renewable energy solutions, industrial buildings can significantly reduce their long-term energy expenses and carbon footprint.

4. Sustainable Materials and Construction Practices

The materials used in industrial construction play a major role in sustainability. Eco-friendly materials reduce environmental impact while enhancing building longevity.

Sustainable Building Materials for Industrial Architecture:

- Recycled Steel and Concrete: Reduces waste and lowers production emissions.

- Bamboo and Engineered Wood: Provides strong, renewable alternatives for industrial framing.

- Low-VOC Paints and Coatings: Improves indoor air quality and reduces harmful emissions.

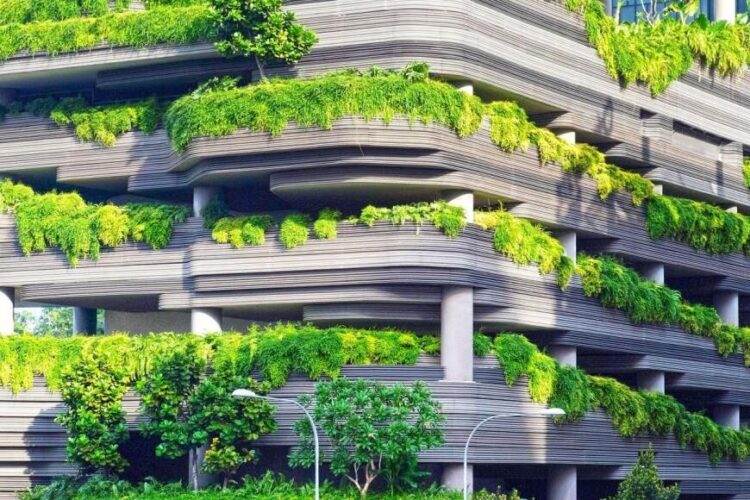

- Green Roof Systems: Enhances insulation and stormwater management.

Using sustainable materials ensures that industrial facilities are built with minimal environmental impact and maximum efficiency.

5. Waste Reduction and Water Conservation

Industrial sites generate significant waste and water consumption. Sustainable architecture incorporates solutions to reduce waste production and optimize water usage.

Waste Management Solutions:

- Recycling and Reuse Strategies: Repurposing materials within the facility to reduce landfill waste.

- Zero-Waste Manufacturing Plants: Facilities aiming for full waste recycling and circular economy models.

Water Conservation Strategies:

- Rainwater Harvesting: Collecting and reusing rainwater for industrial cooling and sanitation.

- Greywater Recycling Systems: Treating wastewater for secondary uses, such as landscaping or equipment cooling.

- Low-Flow Fixtures and Smart Water Sensors: Reducing unnecessary water consumption.

These methods help industries cut down on water waste, lower costs, and maintain sustainable production practices.

6. Smart Technology for Sustainable Operations

The rise of Industry 4.0 has introduced smart technology into industrial architecture. AI-driven automation, IoT monitoring, and real-time energy tracking improve sustainability and efficiency.

Smart Industrial Design Features:

- IoT Sensors: Monitor temperature, humidity, and energy usage in real-time.

- Automated Climate Control: AI-driven HVAC systems adjust temperature settings based on operational needs.

- Predictive Maintenance Technology: Reduces equipment failures and optimizes performance.

By implementing smart technology, industrial facilities can improve efficiency, reduce waste, and enhance sustainability efforts.

7. Sustainable Design in Food Processing Facilities

Food processing plants require specialized sustainability measures to handle temperature-sensitive products, hygiene standards, and resource consumption.

Sustainable Features in Food Processing Facilities:

- Energy-Efficient Refrigeration: Minimizing energy use while maintaining food quality.

- Biodegradable Packaging Facilities: Reducing plastic waste in food production.

- Eco-Friendly Sanitation Systems: Using non-toxic cleaning solutions to meet hygiene regulations.

For expert designs in food processing sustainability, architecte usine agroalimentaire Stendel + Reich specializes in creating high-performance, eco-friendly food production facilities that comply with industry standards while reducing environmental impact.

8. Future Trends in Sustainable Industrial Architecture

Industrial facilities are constantly evolving to meet climate goals, government regulations, and technological advancements.

Emerging Trends:

- Net-Zero Industrial Buildings: Facilities that produce as much energy as they consume.

- Circular Economy Design: Industrial sites that repurpose waste and materials.

- Carbon-Neutral Manufacturing Plants: Factories implementing green energy and offset programs.

These trends will shape the future of sustainable industrial architecture, making factories and warehouses greener and more efficient.

Conclusion

Sustainable solutions in industrial architecture are no longer optional; they are a growing necessity for reducing environmental impact, cutting operational costs, and meeting regulatory demands. Energy-efficient designs, renewable energy integration, waste reduction strategies, and smart technologies are transforming the industrial sector into a greener, more sustainable industry.

By incorporating these solutions, architects and engineers can create future-ready industrial spaces that support both business growth and environmental responsibility. Whether designing manufacturing plants, food processing facilities, or distribution centers, sustainability remains at the core of modern industrial architecture.