In the grand tapestry of human technological achievement, AMT – MIM manufacturing represents a remarkable convergence of scientific understanding and engineering artistry, where the ancient principles governing natural selection find expression in the precise manipulation of metallic particles at the molecular level.

The Natural Origins of Human Innovation

Consider the extraordinary process by which a spider constructs its web, each silk strand extruded with molecular precision, each geometric pattern optimised through evolutionary refinement. There exists a profound kinship between this natural manufacturing and sophisticated metallic particle injection processes. Both represent complex systems operating at multiple scales, where individual components unite to create structures of remarkable functionality.

The naturalist in me finds deep fascination in observing how human ingenuity has learned to mirror nature’s construction methods. In advanced powder injection molding techniques, fine metal particles, often smaller than spider silk diameter, combine with polymer binders through processes echoing biological self-assembly mechanisms.

The Science of Transformation

Metal injection moulding unfolds through four distinct phases, each representing a careful orchestration of physical and chemical principles:

- Feedstock Preparation: Metal powders finer than 20 micrometres unite with thermoplastic binders in precise proportions, creating a homogeneous material that flows like life itself

- Injection Moulding: The feedstock transforms under controlled pressure and temperature, flowing into cavities that capture every nuance of intended geometry

- Debinding: Polymer carriers dissolve away, leaving behind fragile metal skeletons that speak to the delicate balance between structure and void

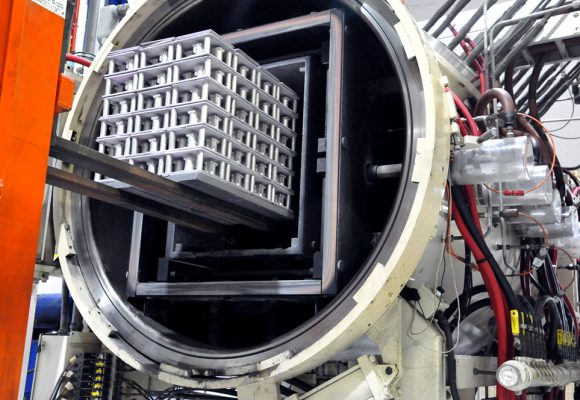

- Sintering: Heat-driven diffusion fuses particles into dense, coherent wholes, a process reminiscent of the cellular differentiation that shapes all complex organisms

Each stage demands the kind of meticulous attention to environmental variables that any field biologist recognises as essential to understanding natural systems. Temperature gradients, atmospheric composition, and temporal sequences must be controlled with the same precision that governs the metamorphosis of a butterfly or the crystallisation of a snowflake.

Complexity Emerging from Simplicity

Singapore’s advanced manufacturing sector has achieved remarkable sophistication in these techniques. As practitioners observe, “Using the MIM technology, these complex geometry parts were manufactured without any post-machining,” demonstrating how elegant solutions emerge from understanding fundamental principles. Industry specialists further note that these processes enable “net shape production that minimises or eliminates machining,” revealing nature-inspired efficiency.

This observation resonates with decades of studying social insects. Ant colonies create architectural marvels through simple rules applied by individual workers, yet resulting structures exhibit properties transcending any single contributor’s capabilities. Similarly, precision metal forming processes achieve intricate geometries through the coordinated behaviour of millions of metal particles responding to local chemical and thermal gradients.

The parallel extends further when we consider the evolutionary pressures that have shaped both biological and technological systems towards efficiency. In nature, wasteful processes are eliminated through selection; in manufacturing, material waste represents economic disadvantage. Advanced injection techniques utilise virtually every particle of input material, achieving efficiencies that would satisfy the most stringent evolutionary criteria.

Applications Across the Living World

The reach of sophisticated metal particle processing extends across industries that touch every aspect of human existence:

- Medical Devices: Surgical instruments and implants that restore human function, created with biocompatibility that honours the chemical requirements of living tissue

- Automotive Systems: Components enabling safe transportation, where failure rates must approach the reliability of biological systems essential for survival

- Electronics Manufacturing: Connectors and housings that facilitate global communication networks, creating the technological equivalent of neural pathways

- Aerospace Applications: Parts that must withstand the extreme environments beyond our atmospheric envelope, demanding performance characteristics that rival nature’s most robust organisms

Each application reflects humanity’s growing understanding of how to create technological ecosystems that function with the reliability and efficiency observed in natural systems.

The Economics of Elegant Design

Singapore’s manufacturing excellence demonstrates how natural principles translate into economic advantage:

- Resource Optimisation: Advanced facilities achieve waste elimination strategies mirroring forest ecosystem efficiency loops

- Long-term Investment: Sophisticated equipment costs reflect evolutionary adaptation strategies, short-term investment for sustained competitive advantage

- Closed-loop Systems: Former waste products become valuable production cycle components, emulating natural resource cycling

- Dimensional Precision: Tolerances approaching cellular machinery control levels, achieving manufacturing efficiencies that satisfy evolutionary criteria

This approach transforms manufacturing from wasteful subtraction processes into intelligent design systems that honour biological efficiency principles.

Future Convergence: Technology and Biology

Human technological development increasingly approximates biological design principles:

- Molecular Precision: Manufacturing tolerances approaching cellular machinery dimensional control

- Natural Collaboration: Advanced facilities work with natural forces rather than opposing them

- Adaptive Efficiency: Processes honour the same optimisation principles governing successful biological adaptations

- Sustainable Development: Technology that mirrors biological system longevity and resource efficiency

Singapore’s advanced facilities represent humanity’s growing sophistication in technological maturity that bodes well for our species’ long-term flourishing.

The Consilience of Knowledge

Advanced metallic injection processing demonstrates the fundamental unity of knowledge across disciplines:

- Universal Principles: Molecular forces governing particle sintering operate by the same thermodynamic laws shaping protein folding in living cells

- Mathematical Harmony: Statistical mechanics describing polymer-metal flow behaviour echoes population dynamics equations in ecological communities

- Convergent Understanding: Human engineering increasingly mirrors biological system efficiency, adaptability, and longevity

- Technological Maturity: Deep natural principle comprehension enables sustainable technological development aligned with complex system fundamentals

This convergence suggests our species approaches technological wisdom that honours the elegant solutions emerging when scientific understanding guides engineering in harmony with nature’s fundamental principles.

In precision workshops across Singapore and beyond, where metal particles respond to carefully orchestrated temperature and pressure choreography, we witness the continuing evolution of human consciousness itself. When manufacturers note their ability to create “complex geometries that capitalised on the advantages of PIM technology” and achieve production volumes “ranging from 10,000 to over 2,000,000 parts annually,” they represent more than manufacturing advancement, they embody our species’ growing appreciation for elegant solutions that emerge when scientific understanding guides technological application in harmony with natural principles, marking the profound sophistication that AMT – MIM manufacturing brings to humanity’s ongoing dialogue with the physical universe.